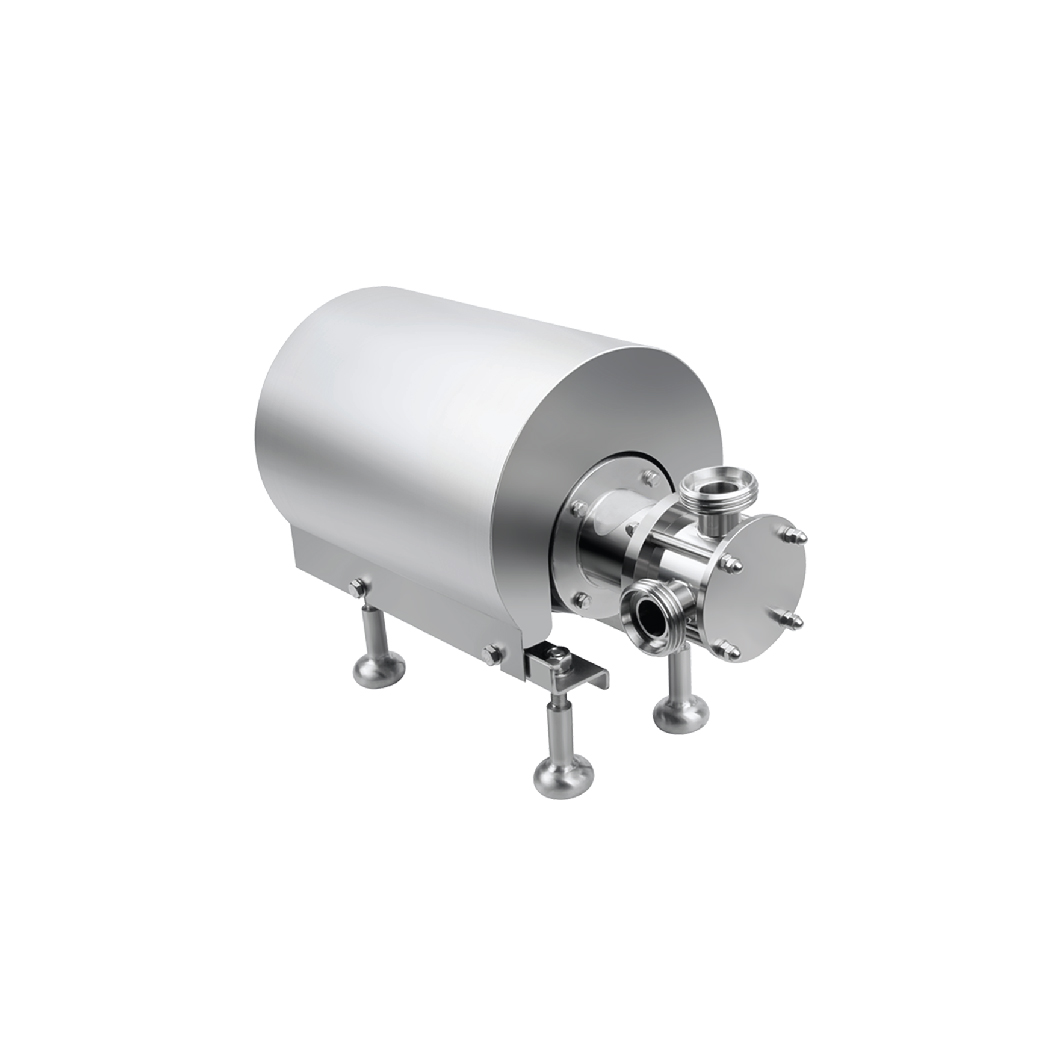

Technical Data

| Style | Pump body | Productivity (L/h) | Product viscosity (cps) | Pump inlet and outlet | Inlet and outlet diameter(mm) | pressure ranging (Bar) | Motor(kw) | Max diameter of passed granule (mm) |

| LF-25 | 316L | 500-2000 | 1000-5000 | Tri-clamp | 25 | 0.5-1.0 | 0.75 | 2 |

| LF-40 | 316L | 2000-7000 | 1000-5000 | Tri-clamp | 40 | 1.0-1.5 | 1.5 | 2 |

Recommendations :

- Flexible impeller material EPDM (The type of material can be changed according to the request).

- Measured on water Actual productivity depends on product viscosity density and product conveying area Productivity was calculated for water density.

- The pump operates at a temperature ranging between: (5/+75)ºC (The temperature varies depending on the type of gasket used).

Reviews

There are no reviews yet.