Technical Data

| Style | Homogenizers body | Productivity (L/h) | Product viscosity (cps) | inlet and outlet | Minimum fineness of product (microns) | The capacity of the motor (KW) | R.P.M |

| H-Mixer-5 | 316L | 500-4000 | from 5000 | Tri-clamp | 25-100 | 4 | 2800 |

| H-Mixer-10 | 316L | 1000-8000 | from 5000 | Tri-clamp | 25-100 | 7.5 | 2800 |

Recommendations:

- Measured on water Actual productivity depends on product viscosity density and product conveying area Productivity was calculated for water density.

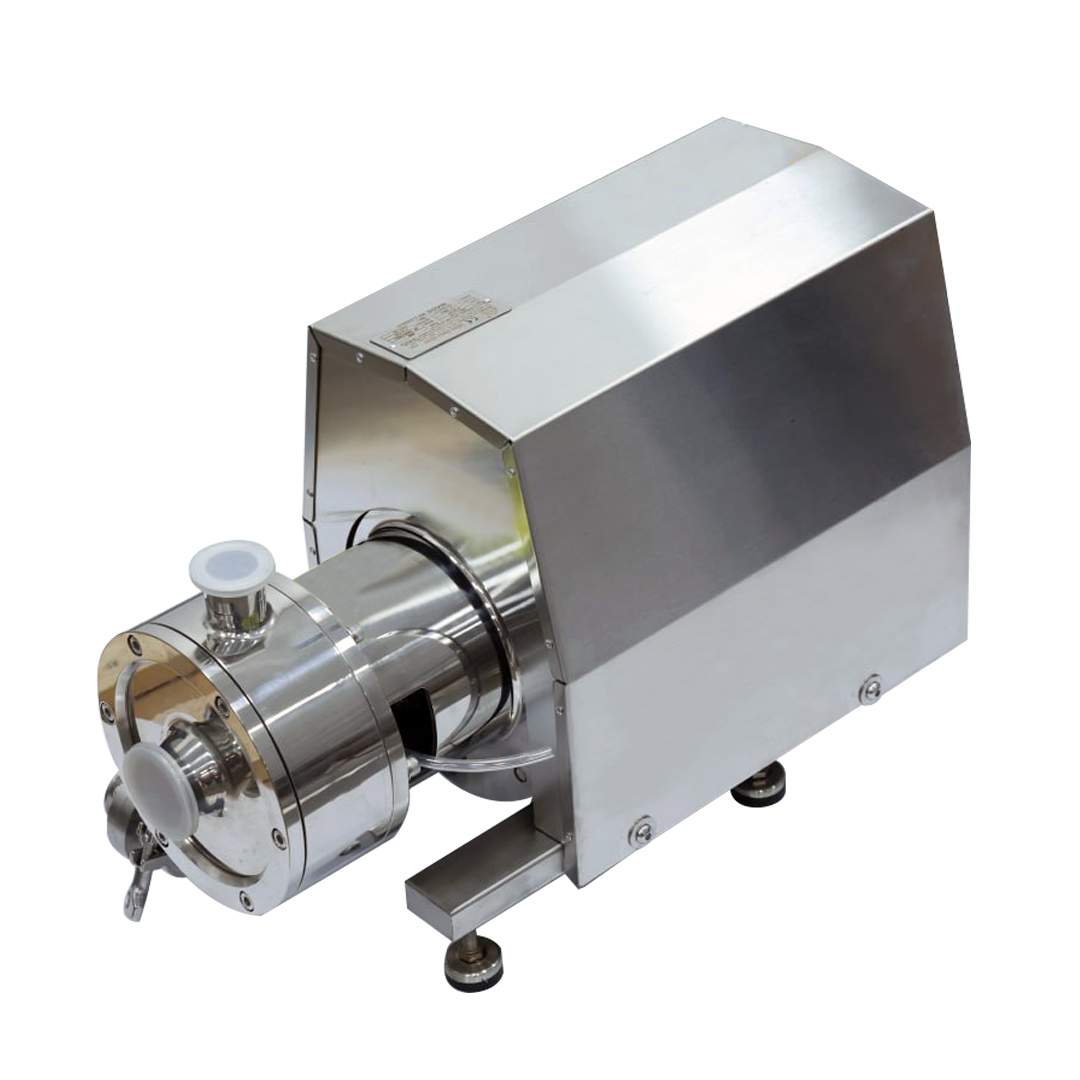

- The homogenizer is mounted on a base with a covers 304.

Reviews

There are no reviews yet.